The word "denim" means "jeans cloth". It is derived from serge(the French word for twill) "de Nîmes", a French fabric woven in Nîmes as early as 1557, originally a blend of wool and silk. Twill is a thick fabric whose weft (the transverse thread) passes under two or more warp threads (the longitudinal threads). "Modern" denim is a sturdy cotton fabric produced in the early 19th century in the USA using European twill methods. Indeed, jeans were created between Genoa and Marseilles in the 1800s. The color of the warp yarn was indigo blue, hence the expression "Genoa blue", which later gave rise to the name "Blue Jeans" through various deformations and pronunciations.

"Made in Japan" jeans

For many people in the Western world, when they think of jeans, it's easy to picture the various forms of advertising for these pants. From the cowboy and working-class Levi's ads of the 1920s, through the 2000s with sculpted, topless men and women wearing nothing but Calvin Klein jeans, to today's all-vintage dress models. Both the presentation of the garment and what it represents have evolved a lot.

American jeans

American jeans, originally a workman's garment, have become an iconic fashion item the world over, symbolizing youth, rebellion and comfort. Advertisements often feature attractive young models wearing jeans in different contexts, to promote different brands and styles. Major brands such as Levi's, Wranglers and Diesel use a sleek, modern aesthetic to promote their products, while emphasizing their attachment to craftsmanship reminiscent of the cowboy era. Emphasis is placed on the qualities (sturdiness and longevity) of jeans, often highlighting their ability to resist wear and tear and remain fashionable for years to come. Representations of American jeans in advertising also reflect the cultural values and aspirations of the target audience, such as freedom, independence and individualism.

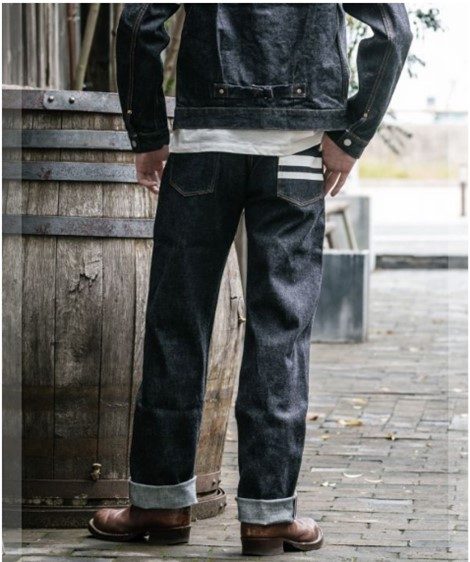

Wrangler® Cowboy Cut® jeans 2023

Asphalte brand jeans

European jeans

European jeans are an essential element of European fashion. Its representation in advertising reflects its quality and style. Advertisements often highlight the durability, fit and unique design of jeans. Its versatility for both casual and formal occasions is also highlighted. Many campaigns highlight the strength of European denim brands, emphasizing their commitment to environmentally-friendly production processes. European jeans are truly appreciated for their quality, sartorial style and socially responsible manufacturing practices.

Vintage jeans

Vintage jeans have become increasingly popular in recent years, with many brands using them as a representation of nostalgia and authenticity. Advertisements often show elegant, attractive people wearing jeans. They emphasize their robustness and timeless appeal. What's more, vintage jeans are often associated with sustainability and environmental awareness, as they can be recycled, reused and bought second-hand. Overall, vintage jeans have become a symbol of fashion and social consciousness.

Levi's 2022 ad

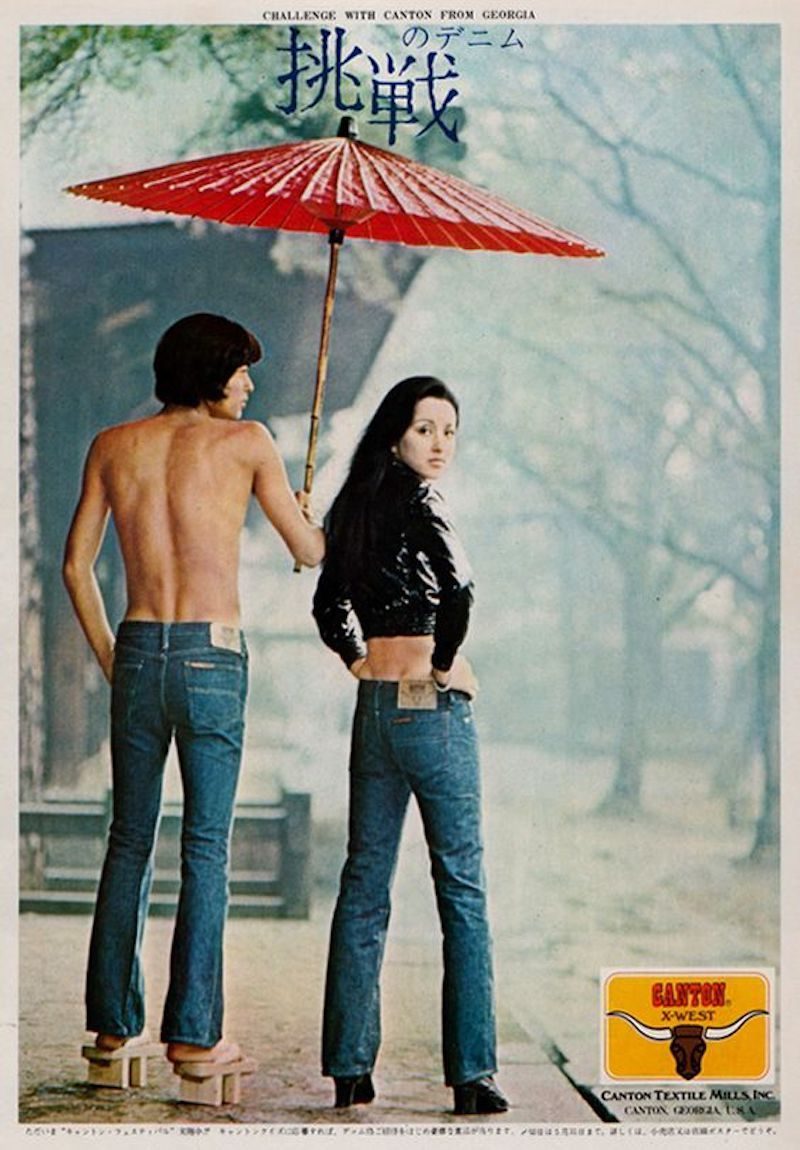

Advert for GU brand Japanese jeans

Japanese jeans

Japanese jeans have gained worldwide popularity thanks to the superior quality of their materials and the expertise of their manufacturers. Representation in advertising emphasizes selling points around the durability of denim fibers and the complex techniques used to create washes and finishes. Japanese brands use unsophisticated aesthetics and imagery to showcase their products, with attention to detail coming at the point of purchase. These jeans are a popular choice worldwide for those who appreciate authenticity and high-quality fashion

Historical evolution of jeans in Japan

Having looked at how jeans are represented around the world through advertising, let's now focus on how jeans are manufactured in Japan and how this process has changed.

Denim, the textile of which jeans are made, only began to make an appearance in Japanese fashion in the mid-twentieth century, after the Second World War, when the American occupation of Japan sparked waves of interest in fashion and pop culture from the USA. So, in the USA, denim jeans have a much longer history than in Japan, since that's where they were first manufactured and popularized as pants, then used for a variety of garments. Surprisingly, denim jeans produced in Japan today can boast qualities that make them distinctly equivalent, if not superior, to those produced in the USA. Denim made in Japan is no longer simply an "American fabric", but a Japanese fabric in its own right, and has become the embodiment of exclusive dyeing and weaving traditions.

The unique characteristics of Japanese denim

Indigo denim

While denim fabric in the USA is dyed with artificial products, in Japan it is hand-dyed with natural dyes from the Japanese indigo tree, Indigofera tinctoria. The finest Japanese denims are handcrafted in Japan using methods dating back to ancient times. Indigo cultivation dates back to the 7th century, when Japanese craftsmen learned to extract deep, dark shades of blue using these plants. In Japan, indigo dyeing was initially used only for clothing worn by aristocrats and samurai. However, by the 17th century - two centuries before the USA saw its first pair of denim jeans - Japanese indigo dyeing had already been popularized for dyeing household fabrics worn by the common people, including kimonos and hand towels. Today, the characteristic Japanese indigo, passed down from generation to generation, is unique to many high-end denim products, which are manufactured in the Japanese prefecture of Okayama, the Mecca of denim.

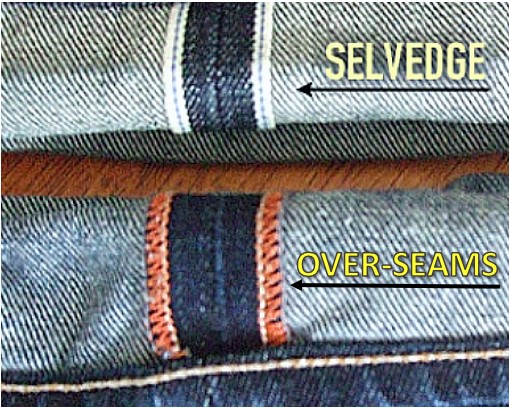

Selvedge fabric

The other important quality feature of denim is the fabric from which it is made. Selvedge, from the English expression "self-edge", refers to the natural end of a roll of fabric that prevents the material from fraying when used to make a garment. The selvedge edge is one of the most distinctive aspects of Japanese denim.

What is Japanese selvedge denim and what makes it so unique? Primarily, it's the way it's made. Selvedge denim is more expensive to produce, as it can only be woven to a width of 31 inches (78.74 cm) - about half the width of non-selvedge denim - and is woven on ancient shuttle looms that require more skill and know-how. The weave is tighter and denser, and has various imperfections. The selvedge of Japanese selvedge denim is usually woven with a characteristic red stripe, although green, white, brown and yellow are not uncommon.

History of Japanese denim

The fashion concept of denim garments may be considered imported to Japan, but high-end Japanese denim has its own history.

In the 1950s, due to the demands of globalization and mass production, almost all denim mills in the USA opted to abandon their shuttle looms in favor of projectile looms, which produce far more denim in larger widths at much higher speeds. This decision reduced production costs, but also compromised certain qualities.

In particular, unlike shuttle looms, projectile looms don't weave denim with continuous threads that create fabrics with clean, sealed edges (a fabric known as selvedge denim). Instead, they weave denim by pulling on individual, unconnected strands, producing fabric with frayed edges. This is how denim began to require seams to stop this fraying. These distinctive over-seams or have become a signature of industrial jeans.

The denim industry has developed and been maintained in Japan for several reasons. On the one hand, the market for school uniforms (the main product of Kojima, a town in the Japanese prefecture of Okayama, for decades) declined due to internal competition. On the other hand, in the harsh post-war years, the industry, in need of extra income, accepted contracts to recut old, discarded American jeans to fit Japanese bodies. Until the Second World War, jeans were the garment of choice for the working class and for American GIs when off duty. After the war, jeans became the symbol of youthful rebellion when James Dean was filmed wearing a pair of Lee jeans in the iconic 1955 film Rebel Without a Cause.

American culture and clothing quickly fascinated young Japanese. The more enterprising among them imported classic American jeans, which they resold at high prices. As the fascination with American culture grew, and thanks to the 1964 Tokyo Olympics, the “Taiyōzoku” phenomenon - a kind of rebellious counter-culture that seized on the jeans symbol to challenge the established order - took its place and gained momentum in Japanese society. This high demand, combined with the obsession with American culture and the quest for Japanese perfection, caused jeans production in Japan to take off.

Jeans Street in Kojima Japan

Maruo Clothing - today known as "Big John", a brand that continues to flourish - then had the idea of solving its perpetual denim supply problem: Maruo would manufacture its own denim fabric, which would be much cheaper than American imports. Maruo Clothing had already enjoyed success in 1968 as a jeans manufacturer using imported American denim. Maruo had convinced the famous Cone Mills company to send them scraps, B-rolls and fabric remnants, which were used to launch the first Big John line. Maruo Clothing took a huge gamble by going completely into jeans manufacturing. At the time, this must have seemed a scandalous decision, since hardly anyone in Okayama owned jeans! In the early 1970s, Big John asked a factory called Kurabo to reverse-engineer the Cone Mills fabric on shuttle machines taken over from the Americans and perfected. After several trials, Kurabo finally succeeded in producing the very first 100% Japanese denim in 1972, christened Kurabo KD-8 (the 8 means it was the eighth attempt). The "M" series, produced by BIG JOHN from Kurabo KD-8 denim, became the first pair of Japanese jeans made entirely by their compatriots.

KD-8 Jeans

After this revolution in Japanese jeans production, these same people were to participate in the worldwide vintage craze.

Shuttle loom producing selvedge denim

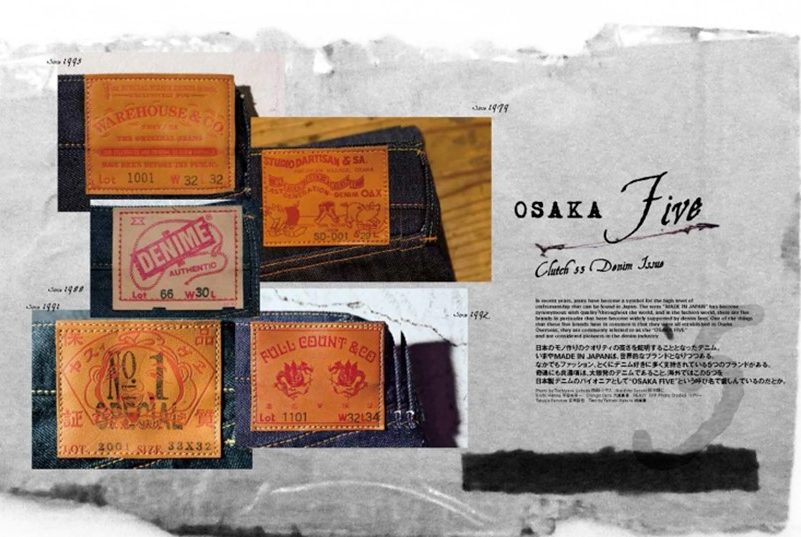

It was in the late 1970s that enthusiasts began to revive vintage production, reintroducing denim garments as a superior product of a bygone era. It's worth noting that this revival didn't begin in the USA, but in Osaka, Japan. Five courageous companies (the "Osaka Five"), the first of which was founded in 1979 (Studio D'Artisan), began re-adopting the weaving methods of yesteryear to manufacture selvedge jeans that had been all but forgotten by the masses. The efforts of the five Osaka companies inspired other regional denim manufacturers, who not only rediscovered selvedge denim, but also pioneered new selvedge styles, dyes and techniques not yet seen in the USA.

The Osaka Five: Fullcount, Warehouse, Denime, Evisu and Studio D’Artisan

While the United States is seeing its number of denim factories shrink (for example, the disappearance in 2004 of Cone Mills, founded in 1895), the Japanese denim industry is as persistent as ever. Denim enthusiasts in Japan already knew the true value of a perfectly crafted pair of jeans. It wasn't until the luxury denim explosion of the late '90s that the rest of the world began to take notice of this burgeoning Japanese denim art and craft.

Hidehiko Yamane, founder of EVISU, pioneered the high-end denim scene by creating some of the world's first high-end denim. Using the same methods as his predecessors, Yamane was able to create 14 pairs of selvedge jeans entirely handmade in one day on old looms, and signed with his hand-painted seagull symbols. These seagull signatures have since become emblematic. The EVISU brand, which originally simply wanted to recreate jeans in homage to the classic Levi's 501 xx, took on a life of its own, earning it a cult following in the streetwear scene. EVISU quickly gained a reputation as the flagship of the best denim brands, and was able to sell each pair of jeans for over $100 - the first denim brand to do so in the '90s.

Luxury EVISU jeans

Other brands continued to experiment with Japanese selvedge denim in search of the perfect pair of jeans, and the global market for luxury denim exploded. Japan Blue Group, based in Kojima, was already known for its high-end denim in Japan and soon began selling to the world's leading luxury brands, such as Louis Vuitton and Gucci. Soon, every fashion house in the world had a line of Japanese jeans. Japan Blue created the Momotaro Jeans label to remain true to its love and respect for jeans.

G001-T Gold Label jeans from Momotaro

Momotaro's G001-T Gold Label jeans are the pinnacle of denim art. Priced at around $2,000, these jeans are entirely handmade and dyed with natural indigo from the Indigofera tinctoria plant. This natural indigo dyeing process goes against what most denim lovers look for in a pair of jeans: jeans don't fade because the dye penetrates to the heart of the cotton. In fact, they often darken with age. Hand-woven on the same loom used to weave silks for kimonos, this particular denim requires up to 8 hours for each meter of fabric. The button closure is made of silver. Once finished, the jeans are washed in Seto sea water. The production of each pair can take up to a year, and even becomes a community event, with local residents taking part in the creation of each pair. Many would scoff at paying $2,000 for a pair of jeans. Denim lovers, on the other hand, find the price reasonable, given the years of tradition, training, craftsmanship and know-how required to create each unique pair.

Japan, leader in denim fashion

The Japanese obsession with recreating the American jeans they loved led Japanese denim brands and manufacturers to become the best in the world in terms of craftsmanship and production. Japan went from being a follower to a leader in denim fashion. Now the global hub for selvedge denim, Japan no longer simply imitates the quality selvedge invented by the USA, but has developed as an innovator in this field of fashion and an advocate of superior quality denim and denim garments. From then on, it was only a matter of time before the rest of the world took notice of the craftsmanship behind Japanese denim.

The unrivalled craftsmanship, the quality of the fabrics, the use of the finest dyes, the choice of top-quality cottons and raw materials and the attention paid to countless details (such as seams, buttons, rivets, pockets and selvedges) have made Japanese denim the most prestigious, the highest quality and, consequently, the most expensive in the world. Japanese jeans are a luxury product, to be bought once in a lifetime and worn forever! Far removed from the disposable philosophy of Western fast-fashion, Japanese denim artisans rely on the concept of "Takumi": a word that describes craftsmanship as a unique way of life, a philosophy that goes far beyond simple manual dexterity.

This Japanese jeans ad illustrates young people's commitment to modernity, represented here by the woman, and their attachment to Japanese craftsmanship and traditions, symbolized by the man's umbrella and "geta" shoes.

Japanese jeans are not simply a Japanese appropriation of American jeans, but a recontextualization of denim in terms of the demands and characteristics associated with it. By approaching jeans as an art form rather than as workwear, Japan has created its own, more refined version of jeans. It has become an art object belonging to timeless fashion, focused on quality, longevity and craftsmanship.

Today, the market is saturated with Japanese denim brands, resulting in a dizzying array of "Made in Japan" jeans. Classic brands are still a safe bet, but many new Japanese denim brands have the same passion and respect for jeans-making as their predecessors.